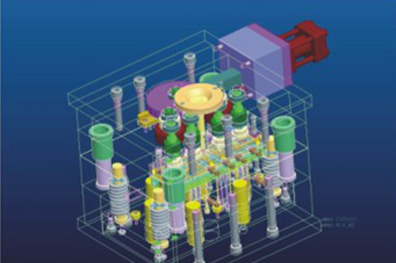

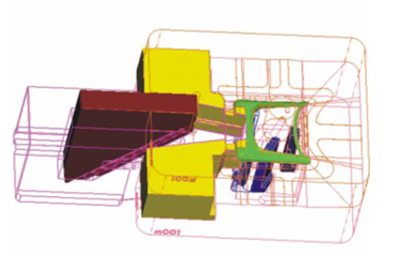

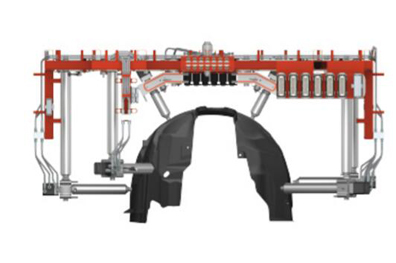

Using the best internationally recognized designing 3D software for completed 3D design to ensure every step will be seamless and intuitive to avoid design mistakes. According to our internal design rules and customers’ tooling specifications,standardizing 3D and 2d design with casual training,all engineers are able to master design rule timely and accurately,and help us reduce repeated mistakes and cost,also improve efficiency.

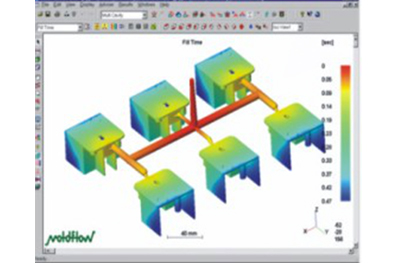

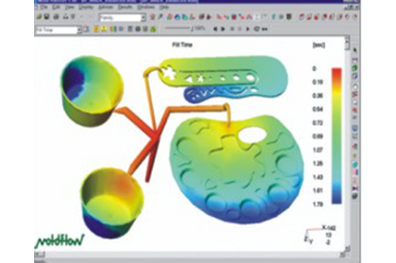

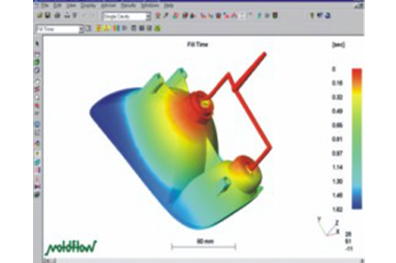

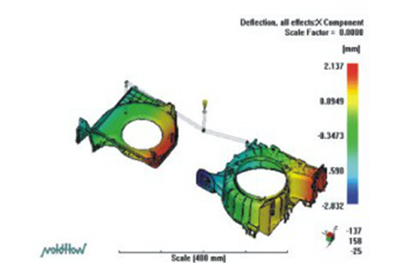

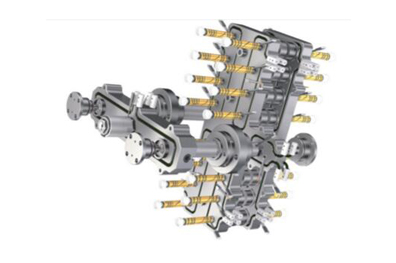

For more products with complicated shape and structure,with CAE software designer make flow analysis,confirm reasonable gate and runner,predict needed injection pressure and clamping force ,and find our the possible defects to offer scientific basis of reasonable mould design. Through CAE technology,shortening mould manufacturing time ,try out and modification times,reducing cost and improved mould and product quality.

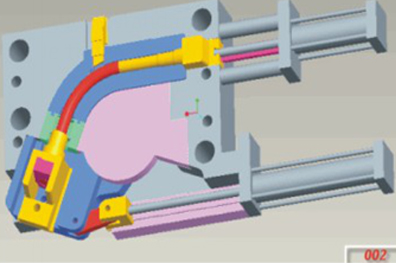

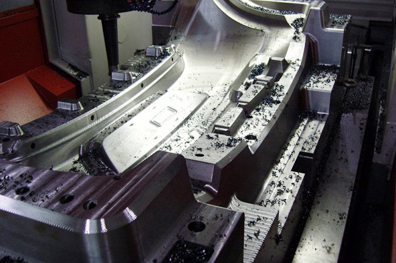

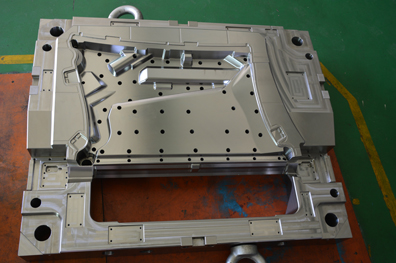

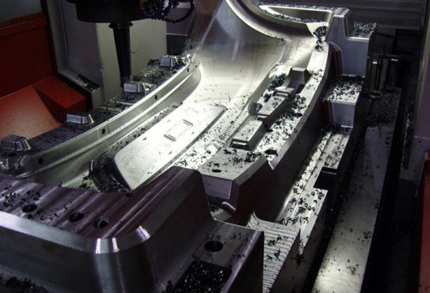

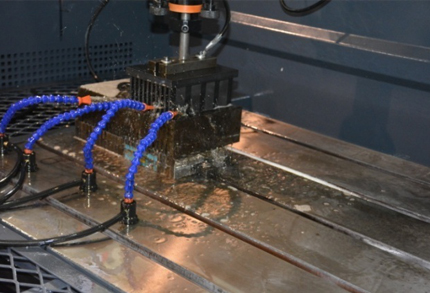

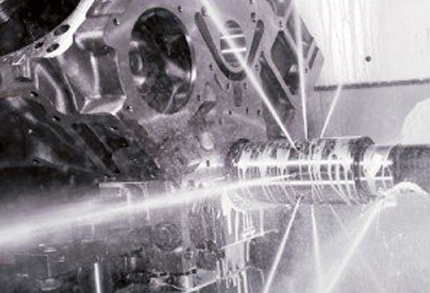

Kewei mold use the most advanced mould CAD/CAM intergrated manufacturing database system.Programming team is made up of a number of experienced elite CAM engineers.